What is a cast-in channel?

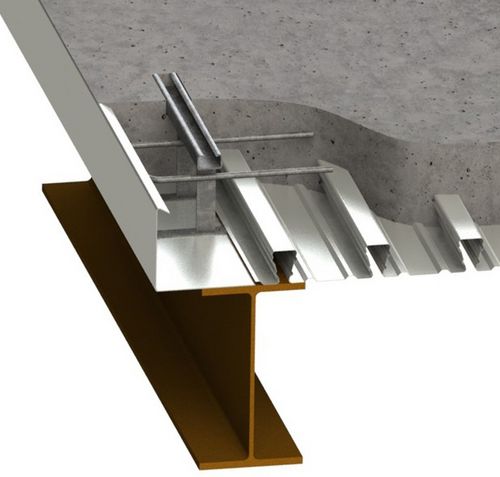

A cast-in channel is a preformed, metal channel commonly made from galvanised or stainless steel, which is embedded into concrete structures during the construction phase. Designed to create a robust and adjustable anchoring system, these channels allow for the secure attachment of various structural elements, such as façade elements, mechanical services, and steel framing components. Cast-in channels are recognised for their versatility and efficiency, offering a seamless integration into concrete slabs, walls, or ceilings without the need for post-installation drilling or welding. This not only streamlines the construction process but also enhances the overall structural integrity and durability of the building. The channels are equipped with T-bolts or similar fastening mechanisms that slide within the channel, providing flexibility and precision in alignment and positioning of attached components.

Features of Cast-in Channels

1. Design Flexibility

Cast-in channels offer remarkable flexibility in design. They can be customised to various lengths and sizes, accommodating the specific load requirements of different projects. This adaptability makes them suitable for a wide range of applications, from simple buildings to complex infrastructure projects.

2. Durability

Made from high-quality materials like galvanised or stainless steel, cast-in channels are designed to withstand harsh environments and provide long-lasting performance. They are resistant to corrosion and can handle significant mechanical stresses, making them a durable choice for any construction project.

3. Ease of Installation

One of the most significant advantages of cast-in channels is their ease of installation. Since they are embedded into concrete slabs or walls at the pre-construction stage, they eliminate the need for drilling post-installation. This not only speeds up the construction process but also reduces labor costs and potential structural damage from post-installation works.

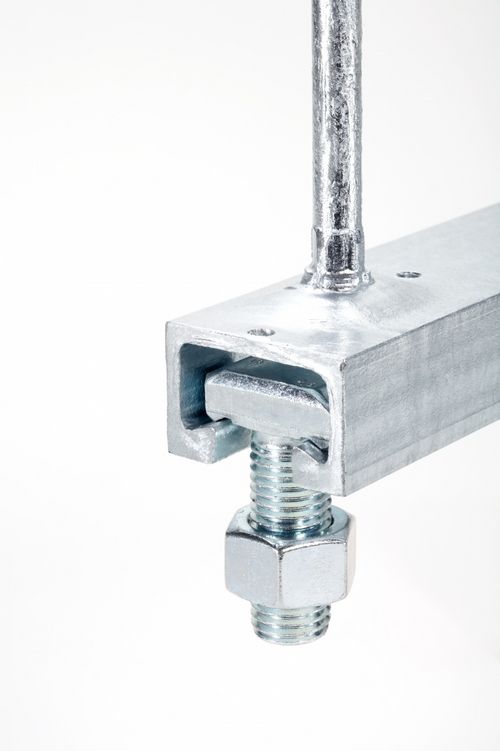

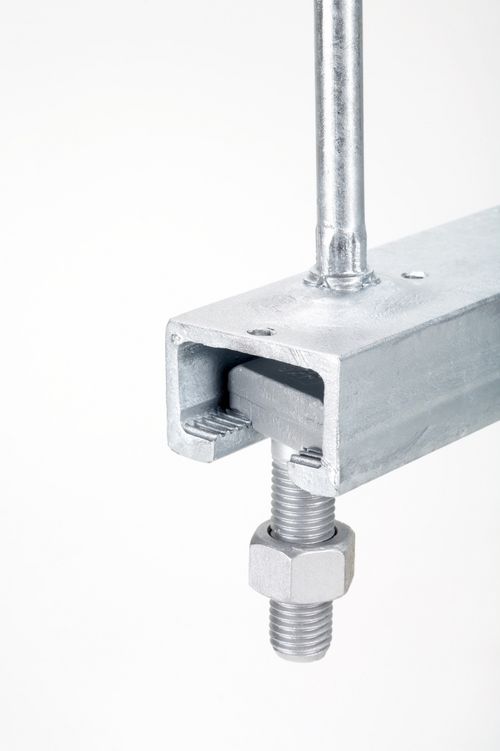

4. Adjustability

The design of cast-in channels allows for adjustable connections. The channels typically come with T-bolts or similar fastening systems that can slide along the channel, providing flexibility in positioning and securing structural components. This adjustability is particularly beneficial when precise alignments are necessary after the concrete has been cast.

Benefits of Using Cast-in Channels

1. Enhanced Structural Integrity

By providing a robust connection method, cast-in channels significantly enhance the structural integrity of buildings. They distribute loads more evenly and reduce stress concentrations at connection points, which is crucial for the longevity and safety of the structure.

2. Cost Efficiency

The initial investment in cast-in channels might be higher compared to traditional connection methods, but they offer long-term cost savings. Reduced labour costs, minimised need for maintenance, and the avoidance of potential damages during post-installation works contribute to overall cost efficiency.

3. Versatility in Application

Cast-in channels are not limited to specific construction types; they are used in various sectors including commercial, residential, and industrial projects. They are also beneficial in retrofitting and renovation projects, where non-invasive techniques are preferred.

4. Sustainability

As the construction industry moves towards more sustainable practices, cast-in channels contribute by reducing waste and energy consumption. Their durability and the ability to be recycled at the end of their service life make them an environmentally friendly option.

The integration of cast-in channels in construction projects offers a blend of efficiency, durability, and flexibility, making them a superior choice for modern construction needs. Whether it's a new build or a retrofit, cast-in channels can significantly improve the structural connections, enhance overall project timelines, and ensure cost-effective execution. As construction technology evolves, the role of such innovative solutions becomes increasingly crucial in meeting both engineering demands and environmental responsibilities.