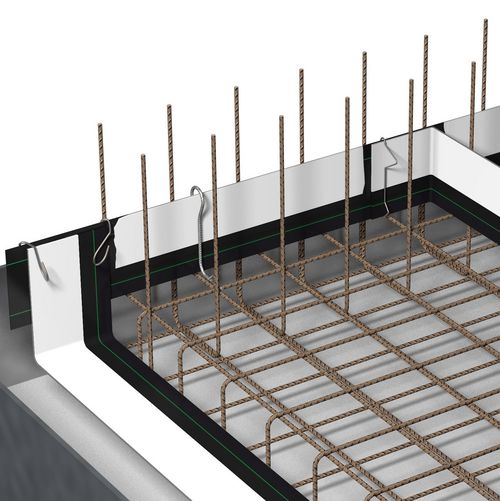

Advances in sealing technology have also been made and coated metal sheet water bars provides the best of both worlds. The sealing system adopted for the coated metal sheet is an active system that reacts with the concrete paste providing a dynamic seal that is active once the concrete has been poured. Coated steel sheet technology is a relatively new system on the market compared to the hydrophilic and PVC tape sealing systems. It is a very versatile system for use on site and needs less workmanship to install. This has many advantages over hydrophilic and standard PVC systems.

The steel strips are provided in 2m longs strips or 25m rolls and are covered with a foil tape that is removed to allow jointing creating continuous water bars. The joint is formed by overlapping the strips by 50mm and pressing the two pieces together. In cold weather, a little heat is required to warm the joining surface. The layout of the basement pour can be adjusted on site to suit works as there is no requirement to have performed joints. The sheet can also be bent to allow for corners of vertical wall junction. The coated steel sheet can be used with standard basement construction as well as twin wall construction. Expansion joints and day joints can be easily accommodated in the system. PVC Tapes can also be joined on to the Steel sheet with locally prepared coated steel sheet sections.

The Coated steel sheet only requires 30mm embedment to achieve the necessary seal to the concrete, so this allows the coated steel system to be placed on top of reinforcement without the need to adjust the steelwork.

The foil on the coated sheet is in two halves, the top foil is to protect the coated sheet from concrete splashes. If the foil is removed, it is not adversely affected by water so can be left exposed ahead of the placement of concrete, this is often the case in twin wall construction. The Coated steel water bar is held in place with straps tied to the primary reinforcement at 1m centres.

As the coating reacts with the cement paste, it provides an active seal and is less prone to system failure providing an effective seal as soon as the concrete is cast.

Contact us for more information